Wood Fire Heater (GBT Boiler)

This is the primary heat source for the property

Quick Reference

| Item | Details |

|---|---|

| Location | TBD |

| Make/Model | GBT Wood Boiler (Geminox) |

| Firewood Location | TBD |

| Min Water Temp | 70°C (to prevent tar/condensation) |

How to Start the Boiler

Before You Begin

- Check water pressure gauge reads above 1 bar (when cold)

- Confirm boiler has electrical power

Step-by-Step Startup

1. PUSH the bypass lever (#3) (opens flue gas bypass)

2. OPEN loading door (#4) → add paper, kindling, then logs

3. LIGHT the paper

4. OPEN ash door (#7) slightly (improves draft)

5. WAIT a few minutes until fire catches

6. CLOSE ash door (#7)

7. PULL bypass lever (#3) toward you (closes bypass)

8. TURN ON main switch (#8) (orange light illuminates)

9. ADJUST temperature knob (#5) (keep above 70°C)

Never use liquid fuel (gasoline, lighter fluid) to light the boiler

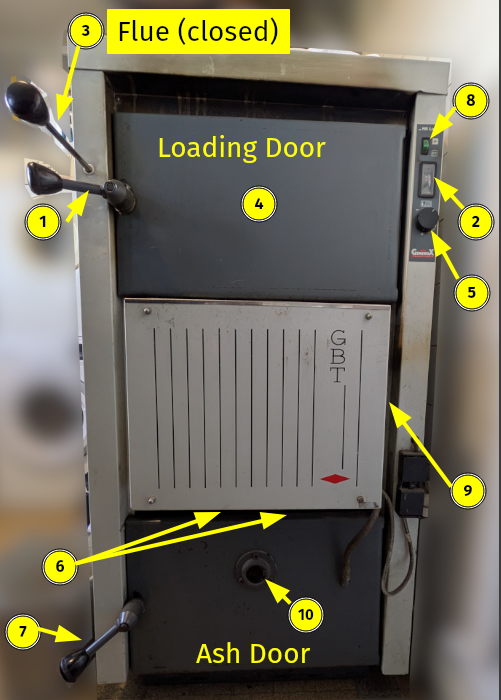

Boiler Components

| # | Component | Purpose |

|---|---|---|

| 1 | Loading door handle | Opens door to add wood |

| 2 | Thermometer | Shows boiler water temperature |

| 3 | Bypass lever | Push to open, pull to close (see below) |

| 4 | Loading door | Add wood here (top front) |

| 5 | Temperature knob | Left = cooler, Right = hotter |

| 6 | Secondary air adjustment | Fine-tune combustion (2 screws) |

| 7 | Ash door handle | Opens door to access ash pan |

| 8 | Main switch | On/Off - orange light when on |

| 9 | Primary air adjustment | Controls main air flow |

| 10 | Flame sight glass | View fire through ash door |

Bypass Lever Positions

| OPEN (for lighting/reloading) | CLOSED (normal operation) |

|---|---|

|  |

| Push lever away from you | Pull lever toward you |

Reloading Wood (Fire Already Burning)

- PUSH the bypass lever (opens bypass)

- Open loading door

- Add wood moderately - prefer 3-4 small loads over 2 large ones

- Close loading door

- PULL bypass lever toward you (closes bypass)

Mid-season advice

Don’t overload the boiler, especially in mild weather. Smaller, more frequent loads are better.

Temperature Adjustment

Boiler Water Temperature

- Turn the temperature adjustment knob:

- Left = decrease (-)

- Right = increase (+)

- Keep temperature at or above 70°C to prevent tar buildup and condensation

Room/Radiator Temperature

- Adjust the mixing valve on your heating circuit (not on the boiler itself)

- Turn gradually from minimum toward maximum until comfortable

Air Controls (Fine-Tuning)

Primary Air (Main Adjustment)

- Air control adjustment knob on front

- Left = less air (slower burn)

- Right = more air (faster burn)

- Goal: maintain glowing ember bed

Secondary Air (Combustion Quality)

- Two adjustment screws near ash door

- Right = decrease air

- Left = increase air

- Adjust with ash door closed

- Check flame through sight glass - should be neither too weak nor too harsh

Shutting Down the Boiler

- Press main switch to STOP position (orange light goes out)

- Keep doors open to ventilate the interior

- Allow to cool completely

Frost Protection

If the building may be exposed to freezing temperatures, contact a qualified professional to add antifreeze or drain the heating circuit.

Summer Operation

If Connected to Hot Water Tank

- Set mixing valve to minimum position

- Keep boiler temp at/above 70°C

- Make 1-2 good batches of dry wood per day rather than continuous low operation

- Adjust hot water temp via thermostat on the tank

If NOT Connected to Hot Water Tank

- Stop the boiler (see shutdown procedure above)

- Leave doors open for ventilation

Prevent Mixing Valve Jamming

Important

During summer, manually operate the mixing valve 3 times to prevent jamming.

Firewood Requirements

Wood Quality is Critical

Use the driest wood possible: 2 years seasoning, including 1 year under shelter

Recommended Wood Types

| Type | Quality |

|---|---|

| Oak | Excellent |

| Hornbeam (Charm) | Excellent |

| Beech | Excellent |

| Maple | Excellent |

| Fruit trees | Good (except cherry & plum) |

Log Sizes

| Model | Max Log Length |

|---|---|

| GBT 20 | 50 cm |

| GBT 30/50 | 70 cm |

Storage Location

TBD - Add firewood storage location

Maintenance Schedule

Daily

- Remove ashes from ash pan

Weekly

- Check central orifice between combustion chamber and loading area is clear

- Remove ash pan and clean exchanger fins with metal brush

- Clean flame sight glass if needed

Quarterly

- Disassemble and clean smoke box (4 screws attach it to boiler body)

Twice Yearly (Mid-season & End of Season)

- Have installer/service check and clean:

- Fan cleanliness

- Air passage openings

- Joint/seal condition

- End of season: complete cleaning, leave doors open for ventilation

Annually

- Professional inspection of all adjustment and safety components

- Chimney flue cleaning and verification

Adding Water Frequently?

If you need to regularly add water to your heating circuit, call a qualified professional immediately.

Troubleshooting

| Problem | What to Check | Solution |

|---|---|---|

| No heating | Wood supply | Ensure boiler has wood |

| No heating | Mixing valve position | Move from minimum toward maximum |

| Heating but no hot water | Hot water system | Call qualified professional |

| Hot water but no heating | Mixing valve | Check it’s not on minimum |

| Smoke in room | Bypass lever | Push open before lighting/loading |

| Poor combustion | Wood moisture | Use drier, well-seasoned wood |

| Tar buildup | Temperature too low | Keep boiler water above 70°C |

| Tar buildup | Wet wood | Use properly seasoned wood |

Emergency Procedures

Chimney Fire

Signs of chimney fire

- Loud roaring sound

- Excessive smoke

- Very hot chimney/stovepipe

- Flames visible from chimney top

If chimney fire occurs:

- Call 112 (fire department)

- Close all air controls

- Get everyone out of building

- Do not use water on the boiler

Carbon Monoxide

- Install CO detector near boiler

- Symptoms: headache, dizziness, nausea

- If alarm sounds or symptoms occur: evacuate and call 112

Water Leak

- Stop the boiler immediately

- Call qualified installer or after-sales service

Service Contacts

| Service | Contact |

|---|---|

| After-Sales Service | TBD - Add local contact |

| Geminox Consumer Service | 08 20 00 60 00 (France) |

| Chimney Sweep | TBD |

| Installer | TBD |

Safety Reminders

Critical Safety Rules

- Never use liquid fuel to light the boiler

- Never overload the boiler, especially mid-season

- Always open bypass lever before lighting or reloading

- Always keep water temperature at/above 70°C

- Never store combustible or corrosive products near boiler

- Never block ventilation openings in the boiler room

- Only qualified professionals may work inside the boiler

Documentation

- Geminox GBT Manual (PDF, French) - Original manufacturer manual

Related Pages

- Heating System Overview

- Fire Emergency Procedures

- Power Outage - Heat during outages